In outdoor spaces, stamped concrete is an innovative and versatile option to achieve aesthetics and functionality features. It is a revolutionary building material that replaces durable high-end brick, slate, and stone. Stamped concrete Contractor in Houston, TEXAS offer an affordable and appealing look for your patios, driveways, walkways, and pool decks. You can have the elegance of traditional masonry with the cost-efficiency of concrete for any construction project.

US Construction is a reliable service that imprints freshly poured concrete matures using molds and color to achieve a stunning look. This technique gives an exceptional appearance and withstands weathering impacts and heavy traffic loads. With innovations, stamped concrete installations retain better color and long-lasting structural integrity for residential and commercial properties.

What is Stamped Concrete?

Stamped concrete is a decorative technique that stamps the concrete poured to resemble other expensive materials. It is textured to look like brick, stone, or wood. It is used to enhance the appearance of outdoor areas with durable and cost-effective solutions.

Applications and Uses of Stamped Concrete in Houston

Obviously, in residential settings, it elevates the advent of driveways and terraces, imparting an economical alternative for pricier substances. Commercial homes use stamped concrete for appealing walkways and entrances. Moreover, it’s also ideal for pool decks, public parks, outside kitchens, lawn pathways, retail flooring, and courtyards because of its aesthetic attraction and resilience.

Commercial Walkways and Entrances

In commercial settings, stamped concrete is used for walkways and building entrances to create a welcoming and professional look. Obviously, Houston Stamped Concrete Contractors provide customized concrete stamping solutions for industrial walkways and entrances, making sure a refined and attractive appearance stands out.

Use in Pool Surroundings

Stamped concrete is a high-quality choice for pool decks because of its slip-resistant surface and potential to face up to water and climate publicity. It additionally provides a touch of beauty to outdoor areas around swimming pools. At our business enterprise, we design and deploy stamped concrete pool decks, which may be very secure and elegant, improving the overall doors revel in.

Outdoor Kitchens and Fireplaces

Stamped concrete gives a great look to our doors, kitchens, and fireplaces. Definitely, our expert creates stunning doors, kitchens and fireplaces with stamped concrete, making sure of capability and a high-end look.

Concrete Stamping in Garden Pathways

Particularly, garden pathways manufactured from stamped concrete are not only long-lasting but also enhance the garden’s aesthetic with their elaborate designs and herbal appearance. At US Construction, we layout and install beautiful lawn pathways with stamped concrete, mixing seamlessly with the herbal beauty of your lawn.

Retail and Restaurant Floors

Stamped concrete is popular in retail stores and restaurants for its durability and ability to face up to heavy foot visitors. Furthermore, it also presents a completely unique and customizable appearance, which could beautify the interior design. We offer stamped concrete floor solutions for retail and eating place spaces, combining durability with custom layout alternatives to fit the atmosphere of your enterprise.

Courtyards and Plazas

In courtyards and plazas, stamped concrete creates inviting and fashionable public spaces. Obviously, its capability to imitate one-of-a-kind substances and styles makes it a versatile desire for massive open regions. At US Construction, we layout and deploy stamped concrete for courtyards and plazas, growing lovely and useful public spaces that invite people to accumulate and enjoy.

At US Construction, as a leading Houston stamped concrete contractor, we offer customized, great stamped concrete offerings for all these packages. We especially ensure beautiful and long-lasting consequences.

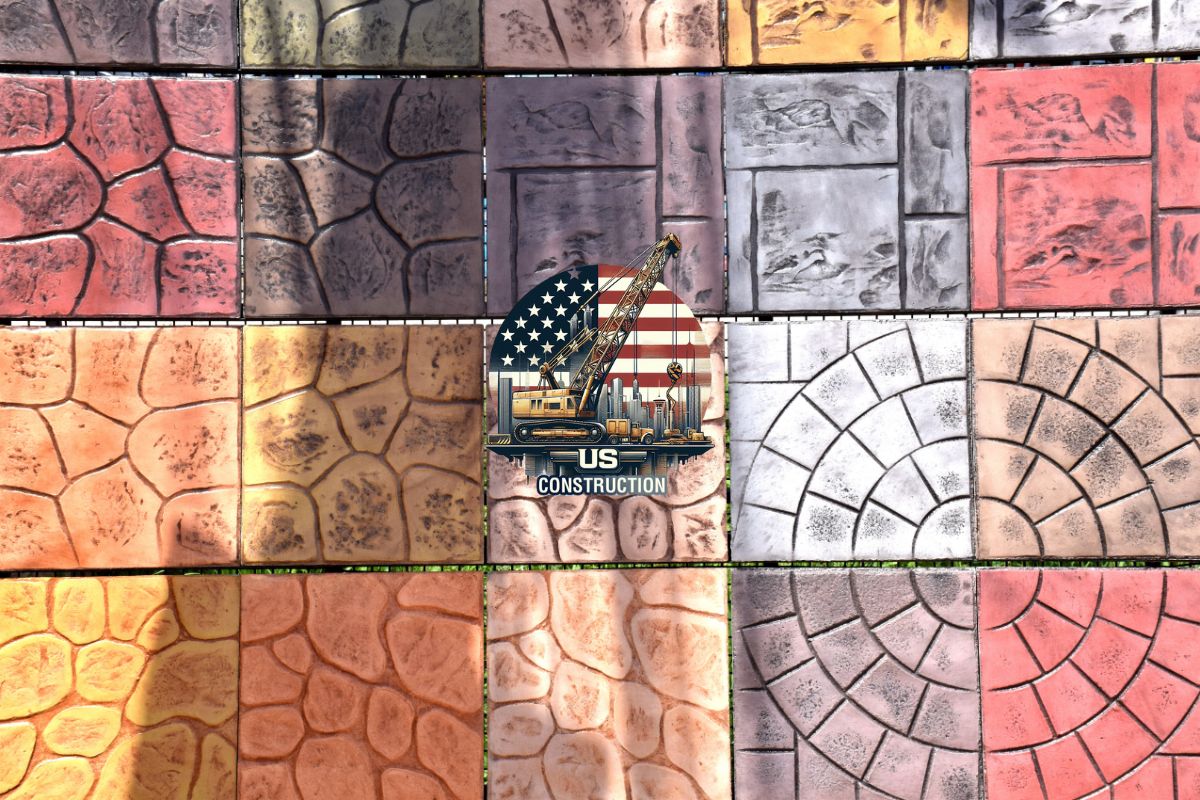

Different Types of Concrete Stamping Patterns

Concrete stamping includes an especially innovative approach to imprint styles and textures onto newly poured concrete surfaces. Additionally, it provides a hint of beauty and expertise to ordinary concrete, reworking it into a visually beautiful characteristic.

This technique permits limitless design possibilities, ranging from complex tile styles to herbal stone textures. Here’s a deeper dive into the different types of stamped concrete:

Brick Pattern

Stamped concrete reproduces the look of old-style brickwork, providing a timeless and classic appearance. Indeed, it is an ideal option to secure driveways, patios, walkways, and garden paths with a traditional and elegant look. Common patterns in this domain are herringbone, running bond, and basketweave. Each type has a different visual effect but the same structural support.

- Herringbone: In fact, the zigzag pattern is the common feature that offers a dynamic and appealing look.

- Running Bond: This pattern gives an image of bricks laid in a staggered design, offering an unvarying and balanced appearance.

- Basket Weave: Additionally, a checkerboard effect is installed for visual interest and complexity to have a durable design.

Colors can be combined into the concrete mix as an integral color or applied to the poured concrete surface using color hardeners. Typical brick pattern concrete is available in red, brown, and gray to real brick color. Moreover, this structure offers the aesthetic appeal of traditional brick. However, the strength and durability of the concrete material reduce maintenance costs.

Stone Pattern

They are designed to alternate the use of various natural stone surfaces, which are costly and fragile. The common designs look like slate, flagstone, or cobblestone. Indeed, these patterns are high-end and powerful with a luxurious look. Usually used for pool decks, courtyards, pathways, and outdoor living areas. Popular patterns include:

- Random Stone: An irregular design is installed to create the natural look of stone.

- Flagstone: These are the duplicates of large flat stones. It is commonly used in car parks and walkways.

- Cobblestone: Resembles to round-shaped small stones near the lakes and waterways. This design gives the look of historic roadways.

- Slate: Obviously, the slate rocks have a uniform texture and a layered appearance.

Well, in such patterns, three different coloring strategies are applied: integral colors, surface-applied or hardeners, and acid stain. The basic color shades varied greatly as the natural stones have different combinations. Typically, the constructors use earthy browns to cool grays. US Construction delivers the upscale look of stone with the outstanding structural support of concrete.

Wood Pattern

Indeed, this is a remarkable attempt to have the charming looks of wood without the susceptibility to rot, insects, and warping. These concrete stamps give luxurious looks and desired durability features. The experts integrate the designs of wooden planks or timber. The common spaces suitable for wooden patterns are patios, interior floors, decks, and garden paths. The color combinations are wood plank, barn wood, and boardwalk.

- Wood Plank: Copy the looks of wooden planks with complete wood grain texture.

- Barn Wood: Reconstructs the appearance of old tree trunks with weathered impacts.

- Boardwalk: Provides a flawless and consistent wood plank appearance.

Integral and stain colors produce realistic wood tones, including browns, grays, and tans. Combining wood’s aesthetic appeal with the endurance and low maintenance facilities. Therefore, it is used in high moisture content areas with heavy use.

Seamless Textures

It creates a continuous, surfaced look without separate or visible joints, offering a smooth and unbroken appearance. Obviously, it is an ideal choice for large areas of pool decks, plazas, and market spaces where a unified look is desired. It uses seamless casings to impart surfaces like sandstone or granite without noticeable lines.

- Sandstone: It offers a fine-grained appearance with a uniform texture.

- Slate: Provides a layered formation that commonly gives a natural look to rocks.

- Granite: Mimics the shape of granite, coarse with crystalline texture.

It can be attained using various color hardeners, integral colors, and acid stain techniques. Indeed, multiple colors should be used to achieve a varied appearance. The flawless texture without any visible joints and lines gives visual continuity to large surfaces.

Ashlar Patterns

These patterns mimic the appearance of a cut stone placed in a specific geometric arrangement. A rectangular formation is often designed to give a sophisticated and precise outlook. Commonly installed over walkways, interior floors, and patios. The patterns most in demand are Ashlar slate, and Ashlar cut stone.

- Ashlar Slate: Structures a mix of quadrangular and square pieces of stones with a slate-like texture.

- Ashlar Cut Stone: Offerings consistently cut stones organized in a geometric design.

Obviously, the earth and gray tones with accent complexion improve the stone’s looks. Moreover, it is achieved by finishing it with integral hardeners and stain coloring techniques. These are versatile and quick substitutes with a sophisticated appearance.

European Fan Pattern

Indeed, a fan-shaped stone layout gives luxurious looks that are commonly installed in European malls and historic courtyards. This pattern provides an old-world charming finish to concrete floors. Suitable for driveways, walkways, courtyards, and garden paths. Fan-shaped patterns replace the stone or brick, producing circular arrangements with an eye-catching design.

It is conveniently installed over varied shades of gray, brown, and red. It offers a unique, ancient aesthetic with the strength of concrete materials.

Basic Process Houston Stamped Concrete Contractor Follow

US Construction being best general contractors in HOUSTON, TX is devoted to rewarding, amazing outcomes that exceed expectations. With years of experience and a dedication to client satisfaction, we ensure that each project is completed professionally.

Moreover, we strive for excellence, transforming ordinary areas into awesome ones. Here’s a step-by-step evaluation of our complete technique:

-

Initial Consultation with Experts

At US Construction, our concrete stamping method starts with a preliminary consultation. We meet with the purchaser to apprehend their vision, options, and requirements for the assignment. Additionally, this includes discussing layout options, color picks, and the particular region to be stamped.

-

Site Preparation

In Particular, our crew clears the area of any debris, grass, or vintage concrete. We then stage the floor and installation forms to outline the shape and barriers of the stamped concrete vicinity. Choose US Construction for stamped concrete because we offer unmatched expertise, careful attention to detail, and high-quality materials.

-

Concrete Pouring

Houston Stamped Concrete Contractors’ next step is to pour the concrete combination into the forms. Definitely, we ensure that the concrete is frivolously unfolded and properly leveled to create an easy floor.

Experts use some protective plastic coverings over mixtures in hot climates to delay the solidification process for perfect results. Likewise, in cooler areas, some additives are integrated into aggregates to speed up the curing.

-

Applying the Color

After pouring the concrete, we apply the bottom shade. This can be finished by adding color directly into the concrete mix or spreading a shade hardener at the surface. At US Construction Houston Stamped Concrete Contractors, we observe a meticulous manner to make certain lovely and sturdy stamped concrete effects.

-

Stamping the Concrete

When the concrete reaches the right consistency, we proceed with the stamping. Also, we press the chosen stamp patterns into the concrete surface, creating textures and designs that mimic substances like brick, stone, or tile. The use of different mold to fabricate the minute details of the stones, bricks, and wood is our distinctive feature.

-

Finishing Touches

After stamping, we practice a release agent on the floor to prevent the stamps from sticking and to add an accent color. Obviously, once the concrete has dried, we clean off the release agent and carry out any essential contact-americano to ensure a regular appearance.

-

Sealing the Concrete

The last step in the stamping concrete process is sealing the concrete. We apply an amazing sealer to guard the surface from stains, weather, and wear. This also enhances the color and look of the stamped concrete, giving it a refined and finished look.

-

Regular Quality Inspection

Before concluding the task, our behavior is an intensive best inspection. Indeed, we make sure that the stamping, coloring, and sealing meet our excessive standards and the purchaser’s expectations.

We end with a last walkthrough with the purchaser to study the completed work. Additionally, we offer preservation pointers and ensure the consumer is glad with their new stamped concrete floor.

Technical Considerations for Reliable Stamped Concrete

Achieving effective stamped concrete designs requires the careful attention of the workers and the technical assistance of reliable tools. In fact, concrete is the most durable construction material and has competitive pricing.

Additionally, the integration of stamping and texturing enhances the aesthetic appeal with durability. These factors ensure the stamped concrete surface’s robustness, flawless finishing, and longevity. Here’s a detailed look at these technical aspects:

Concrete Mix Design

Obviously, the concrete mix should be formulated with a specific proportion to have optimal strength, workability, and durability. The experts settle the composition of the concrete aggregate to meet unique demands. Some parameters affecting the properties of concrete placements are:

Compressive Strength: It should aim for at least 3000 psi (pounds per square inch) pressure tolerance for residential applications. Moreover, 4000 psi or higher strength is required for heavy traffic areas to uphold the commercial settings.

Water-Cement Ratio: Maintaining 0.45, a low water-cement ratio, ensures adequate structural strength. Furthermore, the water content in the optimal range minimizes shrinkage issues.

Aggregate Size: Use well-graded total masses with a maximum size of 3/4 inch to give uniform aggregates with the desired density. This factor ensures a smooth finish and reduces the risk of voids.

Substrate Preparation

A proper subgrade is prepared to settle the materials effectively. Indeed, the surface should adequately prepare for reliable end results. Houston Stamped concrete contractors have the skills and exposure to clear the site to start construction activity.

Compaction: Indeed, achieving at least 95% compaction of the ground surface is important to provide a stable base structure.

Base Material: Use a sheet of crushed stone or gravel. Characteristically, 4-6 inches thickens is paramount. This thickness improves drainage and the concrete slab strength.

Moisture Barrier: A moisture barrier over high water content areas is necessary to prevent cracking and deliver reliable finishing.

Suitable Reinforcement

Obviously, the contractors add metallic reinforcement to enhance the structural integrity. Suitable methods and compositions are essential for premature solidification and minimizing cracking.

Steel Rebar: Using a rebar is the common method, which refers to 3/8 inch or 1/2-inch diameter steel bars spaced 12-18 inches apart. Moreover, the changes depend on load requirements.

Wire Mesh: Alternatively, fused wire mesh can be used with dimensions of 6×6-W2.9/W2.9 for additional tensile strength of the aggregates.

Control Joints Placements

Concrete stamps are uniform structures without any porosity for water infiltration. However, the joint areas need careful sealing techniques to deliver lasting, outstanding designs. Therefore, the control joints cut down cracking by permitting controlled concrete movement.

Spacing: Place control joints at breaks of 24-36 times relevant to the slab thickness. Commonly, it is suggested that the installation be done every 10-15 feet.

Depth: Cut joints according to the slab size, which should be 1/4 the slab thickness depth. Importantly, the 1-inch-deep areas on a 4-inch slab.

Stamping Process

After pouring the specific composition of the concrete mixture, it is stamped to format a texture. In fact, the timing and technique of stamping define the end product. Different types of patterns are installed according to customer needs.

Timing: It is suggested that the stamping process be started when the concrete mixture reaches a plastic state. Conversely, the materials should be firm enough to hold an imprint. Also, it should have enough density to create a clear stamp pattern. Thus, the most suitable time is 30-60 minutes after pouring. Moreover, the weather conditions may vary during this time period.

Stamp Application: Avoid visible seams slightly using consistent pressure and overlap stamps. Ensure appropriate alignment to uphold pattern steadiness.

Coloring Methods

The experts add different types of coloring techniques according to the installed material and surrounding conditions. In fact, the proper coloring techniques must be implemented to attain lasting and exciting hues.

Integral Color: in this protocol, the coloring dye is directly added over the concrete mixture to form a uniform composition. Commonly, 1 pound of coloring pigment is added to 95 pounds of the concrete aggregates.

Color Hardeners: Applying the color hardeners to the concrete surface after the initial fixing. Importantly, this technique is used at 60-100 pounds per 100 square feet rate.

Release Agents: Practice release agents to stop stamps from sticking. The dye is added as a secondary color. Moreover, the application rate is about 3.5 pounds per 100 square feet.

Curing and Sealing

Proper curing and waterproofing tactics are essential to attain maximum strength and robustness factors.

Curing Time: Let the concrete solidify for at least seven days. Afterward, this structure can be used to achieve heavy load-bearing capacity. Indeed, fully cured concrete can typically be reached in 28 days.

Sealer Application: Reliable sealants are definitely important. Therefore, a high-quality UV-resistant sealer protects the tile’s surface and enhances color. Reapply these sealers every 2-3 years, depending on traffic loads and environmental exposures. Moreover, the dosage ratios of these additives are approximately 1 gallon of sealer per 100-150 square feet.

Regular Maintenance

Regular upkeep practices are important to maintain the surface finishing and structural integrity. Moreover, it ensures the longevity and flawless appearance of concrete.

Cleaning: Clean the exterior surfaces regularly with mild cleaner and water to eliminate dirt and debris.

Resealing: Periodically reseal the concrete, commonly after 2 to 3 years, to maintain shield and appearance.

By following these technical attentions and utilizing accurate, data-driven procedures, you can reach high-quality stamped concrete floorings. These structures have aesthetically pleasing looks and remarkably durable results.

Why Choose US Construction for Stamped Concrete

US Construction Stamped Concrete Contractor in HOUSTON, TX are highly experts for exceptional stamped concrete offerings. Obviously, we’re recognized for our unbeatable, long-lasting consequences and creative designs.

With our extensive experience and expertise, we manage each undertaking uniquely and impressively. Our core strengths are popularity, innovative technique, and commitment to excellence. Each mission is approached as a partnership to exceed your expectations continuously.

Advanced Stamping Techniques

Obviously, the latest stamping tools and molds deliver precise and detailed patterns that accurately reflect the real imaging of natural materials.

High-Quality Molds: US Construction utilizes molds that are crafted from real stone, brick, and wood. Therefore, each imprint must capture the complicated textures and particulars of the original material.

Custom Patterns: Moreover, we offer a wide range of synthetic patterns of expensive construction materials at a fraction of their cost. Contact us to have an estimated cost of each design with professional suggestions.

Superior Coloration Methods

Our cutting-edge coloration techniques are outstanding for achieving vibrant and long-lasting colors. Indeed, these innovative assistants enhance the visual appeal of concrete surfaces. Importantly, by mixing the color directly into the concrete materials delivers uniform symmetry with proper color distribution and durability.

Color hardeners and stains penetrate deeply into the mixtures and provide rich and natural hues. In fact, adequate coloring techniques increase resistance to fading and wear. Our high-performance UV-resistant sealers protect the colored surface from sunlight-related damage and retain concrete beauty over time.

Enhanced Durability and Longevity

Our stamped concrete fixings are designed to resist heavy use and severe weather conditions. Therefore, it guarantees exceptional durability and longevity. Moreover, we use integrated specialized concrete mixes with considerable compressive strength. Also, experts provide tailored solutions to withstand Houston’s unique soil conditions.

Incorporating steel rebar into installations boosts tensile strength and reduces the risk of premature cracking. Thus, resulting in a robust and resilient concrete surface. US Construction’s meticulous curing and sealing processes are reliable to prevent early solidifications and cracking. Our structures exhibit extended lifespan and aesthetic appeal.

Customized Solutions

In Houston construction dynamics, the role and impact of its hot and moist climatic conditions impact a lot. We provide personalized solutions that meet the needs and preferences of each client. The experts discuss the backline details and suggest the perfect match for your requirements.

Personalized Design Consultations: Our crew works closely with customers to comprehend their vision. They recommend specific patterns, colors, and finishes according to their use.

Versatile Applications: Indeed, the applications of stamped concrete are diverse. It can cover driveways, patios, pool decks, or walkways. We offer versatile stamped techniques and solutions to enhance the outlook of outdoor spaces.

Sustainable Practices

We are dedicated to environmentally friendly practices to reduce the impacts of construction on natural resources. Obviously, the concrete materials can be recycled to control the waste generation and cost of the projects. Therefore, we considerably apply sustainable materials and methods.

Eco-Friendly Materials: Our concrete blends include recycled resources. Therefore, reducing waste generation at construction sites and conserving natural resources.

Low-VOC Sealers: Indeed, the use of low-volatile organic compounds as sealers control harmful emissions. These compounds impact the health of the workers and nearby.

Efficient Installation Processes: Our approved installation techniques deliver superior results with the least energy consumption. Hence, contributing towards greener practices.

Exceptional Craftsmanship

Our team of trained professionals delivers incomparable craftsmanship. Moreover, they are backed by rigorous quality management measures to deliver top-notch results. Our crew comprises highly trained and knowledgeable technicians who excel in each aspect of concrete installation.

We implement strict quality standards, control measures, and monitoring mechanisms to provide customer satisfaction. Moreover, for the ease of users, we offer after-construction maintenance services and restoration plans.

By connecting with US Construction, an experienced Houston Stamped Concrete Contractor, you will experience innovation, quality, and customer satisfaction. Our forward-thinking techniques, A-grade raw materials, and customized services exceed your expectations.

Contact Us to Enhance Aesthetic Flooring

Transform your outdoor areas with concrete stamped titles to foster environmentally friendly installation with a unique blend of innovation and aesthetics. Indeed, these are timeless elegance under controlled expenses. With our personalized design and exceptional craftsmanship, we enhance the functionality of the outdoors at minimal costs.

Contact US Construction for a free consultation and discuss your specific requirements. Our devoted experts try their best to bring your vision to life. Let partners have stunning, custom-designed concrete flooring ideals that will stand the test of time. Call us or visit our website for more details and get started on your next construction project!

Leave A Comment