In metallic structures of warehouses and industrial units, the selection of steel metal specifications varied according to the proposed functions. Steel metal exhibits unique properties and is used in the construction of homes or commercial buildings. The primary reason for its extensive use is its low price and easy availability.

However, various grades and qualities of steel are available in open markets. This exploration is enough to understand the basic concepts of light vs. heavy steel in metal building construction. US Construction Company is an expert in developing metallic frameworks for different scales and types of operations. Stay with us for more precise information and a comparison of both.

Why Steel Metal is Used in Construction?

Steel’s remarkable mechanical, physical, and chemical qualities. Therefore, it is considered one of the most preferred choices in the construction industry. For readers’ understanding, we elaborate on the key characteristics of steel:

High Strength-to-Weight Ratio

The ratio of mass to its tensile strength is considerably low, which is an exceptional feature. Steel can tolerate the weight loads of a building, but its weight is less. This superior quality makes it feasible in large-scale construction projects.

Contractors can develop high-rise buildings with steel frameworks, eliminating the need for concrete pillars. Its lightweight property resulted in an infrastructure which had the least load on its framework. Therefore, in heavy-duty industrial units, warehousing facilities, and structures such as towering buildings and bridges are constructed with it.

Ductility

The ability to withstand high pressure without altering its shape and strength is another notable feature. Steel has a high elasticity limit and retains its original shape in challenging situations. This security and durability make it an unparalleled solution for metal frameworks.

This feature is convenient in areas prone to high vibration or hurricanes. It permits more adaptable and innovative layouts in addition to improving its durability by reducing unexpected collapse.

Malleability and Workability

Steel is incredibly flexible and resilient to strain. Therefore, it can be molded into any shape and used repeatedly without compromising its durability. Hence, the contractors use steel in time-sensitive projects.

Additionally, prefabricated steel structures are confidently used in construction. The modular components reduce on-site resource usage and enable quick execution of processes.

Toughness

Toughness is defined as steel’s capacity to withstand heat and pressure without breaking or splitting. It is therefore ideal for industrial processing units operating in harsh surrounding conditions. Moreover, in the construction of highways and railways, steel is used.

Durability and Longevity

When steel is treated with zinc or coated with some protective coverings, the speed of metal rusting and environmental degradation is controlled. Therefore, the steel framework is crafted in industries with more exposure to severe temperature and moisture conditions.

Fire Resistance

Steel will work better with fire-resistant coverings. However, at extremely high temperatures, it may lose strength. Steel is a crucial material for structures that need heat-rated assembly. Indeed, it inhibits the expansion of fire, unlike wood and plastic structures. In an emergency, it is essential for both occupant protection and maintaining building integrity.

Corrosion Resistance

In fact, the unprocessed steel is more susceptible to corrosion and weathering-related damage. The experts use the steel after chemical treatments with COR-TEN or after powder coating. Moreover, galvanization is an effective way to cover the metallic structures to reduce surface exposure.

Modulus of Elasticity

The steel metal exhibits a 200 GPa coefficient of elasticity, which enables it to regain its original shape. This flexibility reduces drooping or persistent damage over time.

Moreover, it helps to maintain the framework’s shape under typical loads. This crucial characteristic provides for long-term stability in construction.

Recyclability and Sustainability

Steel can be reclaimed and reused multiple times. The majority of construction-grade steel is composed of durable materials to withstand extensive strain.

This approach promotes sustainability and green construction methodologies. By using steel in infrastructural development, the carbon footprint of construction is reduced.

Predictability and Uniformity

Steel behaves predictably under a range of weights, temperatures, and pressures due to its consistent composition. US Construction Company is a registered Houston general contractor specializing in the delivery of reliable metallic frameworks.

This uniformity makes structural assessments easier, thereby reducing the likelihood of unexpected breakdowns. Moreover, it enables engineers to predict performance with high precision.

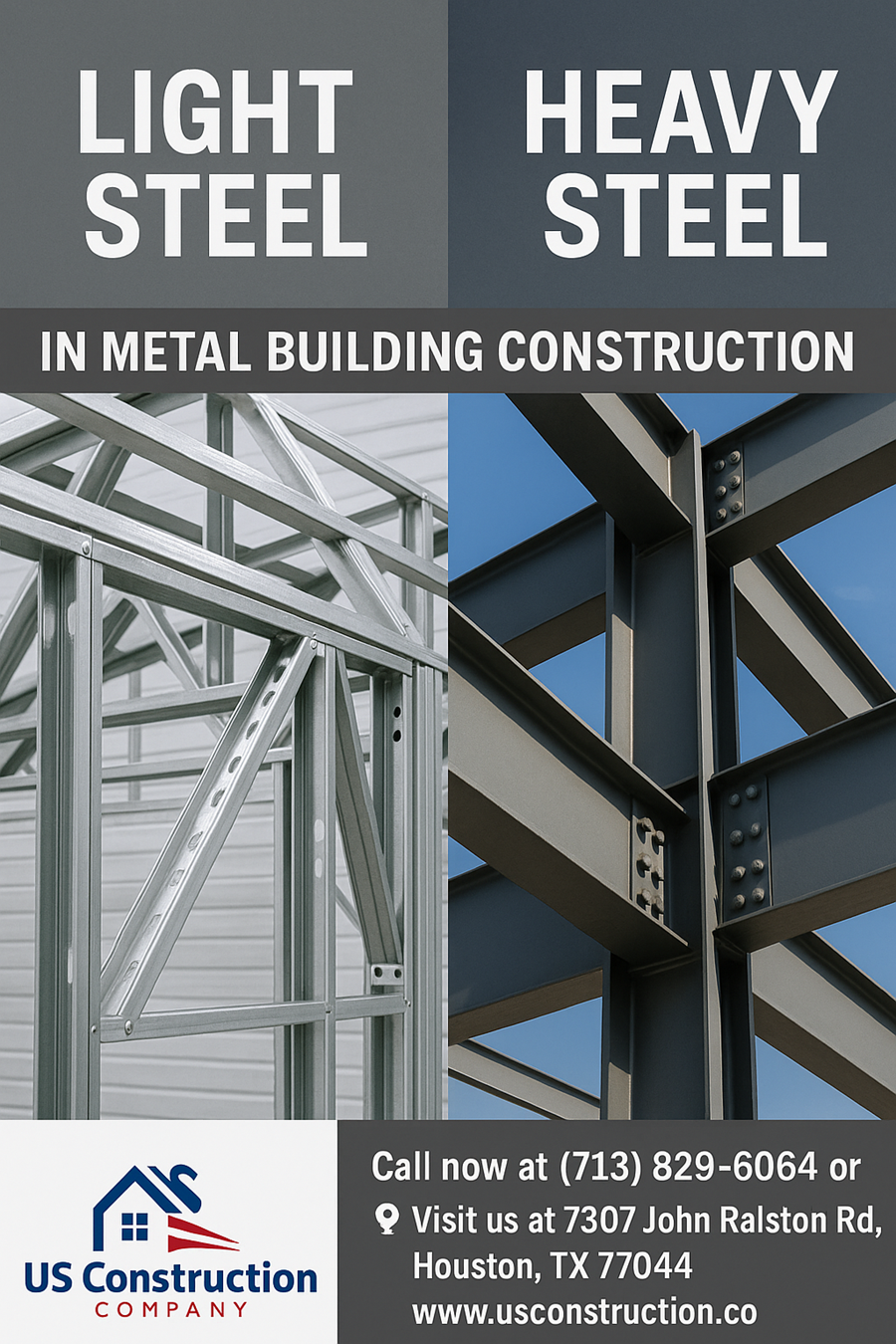

Understanding Light Steel and Heavy Steel

The need and demands for metallic thickness vary with the nature and scope of the project. US Construction is Houston’s best general contractor, who understands where and how steel and metal are used in the framework development of buildings.

What Is Light Steel?

In contrast to conventional heat-based fabrications, light steel, also known as cold-formed or thin-gauge metal, is used. It is composed of cold-forming thin film that is galvanized to craft precise designs. This produces accurate, lightweight parts that are frequently utilized in studs or joist formations.

- Easy and Fast Placement: Lightweight parts are simpler to prepare, move, and assemble, which shortens construction schedules and reduces labor requirements.

- Economical for Smaller Tasks: Perfect for inner structures with low load-bearing capacities or structures up to three stories high.

- Degradation Protection: In humid climates, light steel is the most suitable and remains stable. It also resists corrosion and is zinc-plated for added protection.

- Exceptionally Accurate and Smooth: Strict standards reduce costly errors and scrap production during steel beam assembly.

Light Steel Applications

- Enclosure development of office interiors

- Build Outs for corporate retail spaces

- Compact storage spaces

- Walls dividing a storage facility

What Is Heavy Steel?

Sturdy designs, such as I-beams, H-columns, and massive steel beams, are created by hot-rolling steel for construction, also known as heavy steel. Thick steel beams and pillars are essential for constructing skyscraper buildings.

- Outstanding Strength: It can withstand the heavy weight of the construction and its tenants.

- Flexible Design Options: Enables contractors to design and build towering buildings. Moreover, with high flexibility, it can be reused repeatedly.

- Improved Fire Protection: When coated with additional protection, the steel structure can withstand extremely high temperatures.

Heavy Steel Applications

- Large-scale manufacturing and processing units

- Logistics centers and large-capacity storage

- Sports venues and athletic facilities

- Large office towers for businesses

Houston General Contractor Near Me

The project size, scope, and budget serve as the baselines that define the specifications of steel within the construction framework. Houston general contractors reliably decide whether you use heavy or light steel.

Heavy steel provides greater strength and longevity, whereas light steel is best suited for small-scale, economical constructions. US Construction Company has experts who can select the appropriate material to meet the requirements of your project.

Leave A Comment